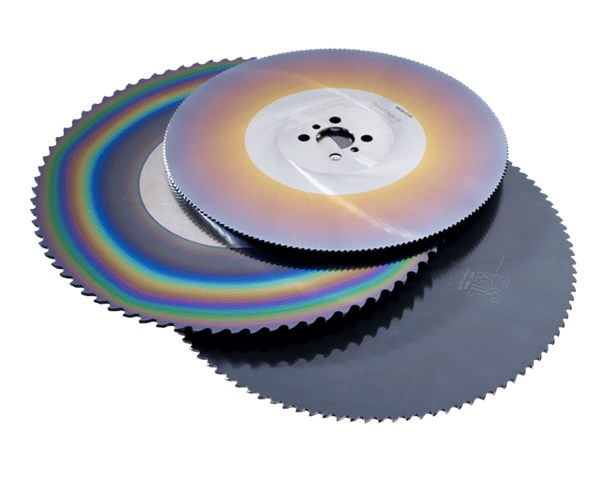

HAOJING, supplying HSS Circular Saw Blade from smelting the raw material to completed blades, and processing the heat-treatment at our own factory. Therefore, we can easily control them high quality and our prices always stay very competitive in the market. Different sizes & teeth forms will be applied to cut different tubes & pipes, with our full experiences, we will support you the local market positioning and help you to break into the local metal industry in short time.

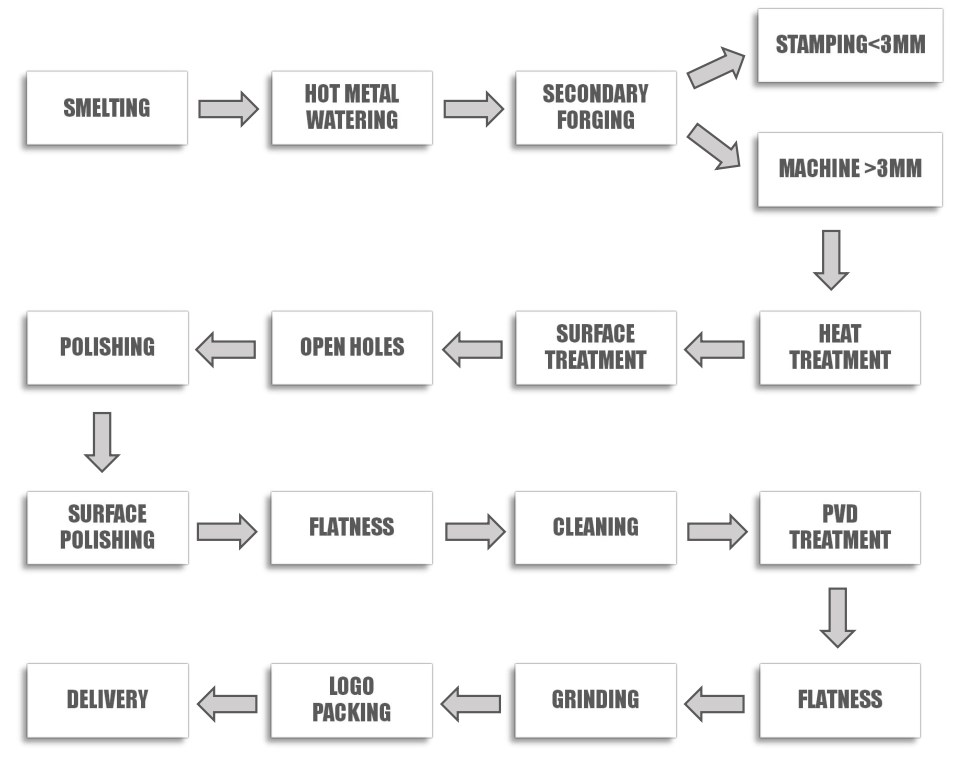

Here is a Summary of HSS Saw Blade Manufacture Processes

1. SMELTING: is a process of applying heat to ore in order to extract a base metal. Either as the element or as a simple compound, from its ore by heating beyond the melting point, driving off other elements as gases or slag and leaving the metal base behind.

2. HOT METAL WATERING: placing the hot metal in cold water has a number of effects. No chemical reaction takes place in the metal. As the heat transfers from the metal, the water heats up and the metal cools down. The metal does not change its state. It remains a solid and keeps stablity.

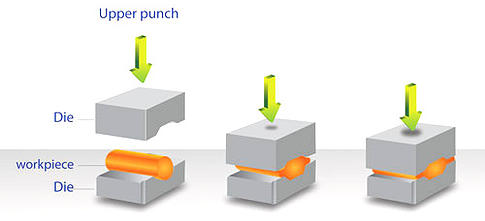

3. SECONDARY FORGING: forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die.

4. STAMPING: stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

5. HEAT TREATMENT: heat treatment of steels is the heating and cooling of metals to change their physical and mechanical properties, without letting it change its shape. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

6. SURFACE TREATMENT: the treatment of metal is a process in which parts or components made out of metal are treated before any actual coating takes place. The purpose of this treatment is increasing the surface energy level of a particular metal surface so that it can easily adhere to PVD coating that is about take place.

7. SURFACE POLISHING: polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion.

8. FLATNESS: the flatness of the saw blade determines the stability during cutting and maximizes the cutting performance.

9. PVD TREATMENT: to guarantee the excellent quality and the best tool performance, we have to coat the HSS saw blades with the right film according to different applications. Together with the hardness of the coating, it is also necessary to guarantee the correct adherence of the coated surface.

10. GRINDING: the geometries can be designed to be straight to almost round, depending on the range of applications of the saw blade. The tooth top is sharpened with a face grinding or peripheral grinding process. Sharpening using a face grinding process is particularly time-saving. A, AW, B, BW toothings are the most commonly applied.

11. LASER LOGO: OEM service is available, which can be customized as your requirements.